LIQUID-Liquid Separations

Transcend Solutions provides advanced liquid-liquid separation technology engineered to capture, coalesce and separate exceptionally small, emulsified droplets. Our systems deliver unparalleled performance in the most demanding process streams, ensuring product purity and operational stability. Our liquid-liquid separations technology can be implemented across the upstream, midstream and downstream sectors using products tailor-made for customer needs.

Contaminant Removal for Equipment Protection and Product Recovery

The Challenge of Stable Emulsions

When two immiscible liquids are mixed, they can form stubborn physical emulsions that are difficult to break. Effective separation depends on leveraging the surface energies, densities and viscosities of the two phases. This challenge is magnified in systems with low interfacial tension or where droplets are exceptionally small, leading to process upsets, product contamination and costly downtime. Traditional separation equipment often fails to meet the performance requirements for these complex applications.

Advanced Emulsion Breaking with Transcend

Transcend Solutions has developed advanced separation and filtration capabilities to overcome the limitations of conventional technology. Our systems are engineered to master emulsion breaking, protecting equipment and supporting product recovery and purification.

Industries Served

Gas Processing Plants

Acid gas treating and dehydration systems

Oil and Gas Production

Upstream applications

Natural Gas Transmission

Pipeline quality gas preparation

Refining

Process gas conditioning and treating units

Petrochemical

Feed gas preparation and product purification

Power Generation

Turbine fuel gas conditioning and compression

Our Proven Process: Simple Implementation, Lasting Impact

01

Assess

Analyze frequency and duration of downtime, process upsets, and off-spec events to trace root causes of contamination.

02

Specify

Perform contaminant characterization, then select media and technology to address specific process needs and compatibility.

03

Deploy

Install upgrades – often without cutting or welding – to minimize disruption. Retrofit solutions leverage existing vessels wherever possible.

04

Monitor

Track filter run life, pressure drop and system performance to optimize change-out cycles, often using facility historian data for validation.

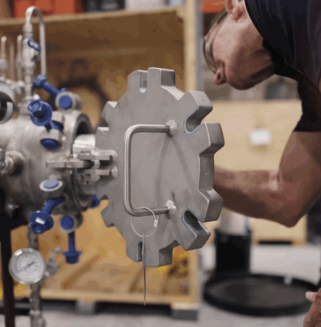

Technical Innovations and Value

High-Efficiency Media Technology

Delivers absolute or beta-rated removal down to sub-micron levels.

No Major Capital Expense Required

Case-validated revenue impacts and OPEX reductions pay back upgrades, often in a single run. This improves operating excellence with minimal investment.

Differential Pressure (ΔP) Monitoring

Supports proactive maintenance and performance validation, reducing labor and enhancing reliability.

Optimized Element Design

Retrofittable to most existing vessels, built for positive O-ring sealing, superior chemical compatibility and ergonomic change-outs.

4-Cs Methodology:

Capability, Compatibility, Characterization and Cost; ensuring each filter is engineered for your exact service and delivers the expected return.

Proven Applications and Custom Solutions for Liquid-Liquid Separation

Key Applications & Services

Our separation and filtration technology is engineered for versatility across a spectrum of challenging scenarios. Whether you need to address contamination, enhance equipment reliability, or improve product recovery, Transcend delivers custom solutions that meet your facility’s unique needs.

Key applications and services include:

- Hydrocarbon/Amine Separation: Prevent carryover of hydrocarbons from rich amine flash tanks and increase SRU reliability.

- Dehazing of Diesel: Remove free water to optimize salt drier performance; eliminating excess salt consumption, bed channeling, and product haze failures.

- Chloride Removal from Reformate: Reduce corrosion risks and protect downstream process units.

- Alkylation: Achieve effective water removal from SHU and C3/C4 streams, supporting stable alkylation operations.

- Hydrotreating: Remove water from product or feed streams, ensuring catalyst longevity and consistent performance.

- Product Recovery: Eliminate overhead accumulator undercarry to minimize losses.

- ·Coker Operations: Eliminate blowdown undercarry to the sour water system, reducing contamination and enhancing processing reliability.

- Batch Chemical Manufacturing: Eliminate product haze, optimize or eliminate wash/decant/neutralization processes through elimination of rag layer interfaces and stable emulsions. Increase plant utilization by minimizing post-reaction processing. Eliminate off-spec product or product re-work due to haze or ineffective separations.

- Sour Water System Optimization: reduce feed/effluent exchanger fouling, reboiler fouling and stripper column instability due to heavy hydrocarbons.

Liquid-Liquid Separation Solutions

Transcend’s field-proven liquid-liquid separation solutions are deployed in these and other demanding hydrocarbon processing environments, supporting operational excellence and long-term asset protection.

- Amine Treating: Prevent hydrocarbon carryover from rich amine flash tanks.

- Refined Products: Perform effective de-hazing of diesel fuel.

- Reforming: Achieve efficient chloride removal from reformate streams.

- Petrochemicals: Ensure complete water removal from Saturated Hydrocarbon Unit (SHU) feeds and C3/C4 streams.

- Hydrotreating: Protect catalyst beds by removing water and contaminants from feedstocks.

After Market Services

Filter Replacements, Lab Testing, Field Services and More

The work to keep our customers’ processes functioning efficiently doesn’t stop once a separator or filtration system is in place. Transcend Solutions is committed to process optimization from start to finish. We’re here to help with filter repurchases, lab testing, field service, rental units and custom manufacturing – all tailored to each customer’s specific needs.